A PLANK

LVL Scaffold Plank

Advances in American wood science and manufacturing technology contribute to the A PLANK advantage. Douglas-fir, a native species of North America was selected for its superior strength-to-weight ratio. Logs are peeled to yield thin sheets of veneer. Each A PLANK consists of mulitple layers of veneer graded by strength and density. Naturally occurring wood defects such as knots and slope of grain are dispersed during the lay-up and lamination process for greater consistency and strength compared to solid lumber planks.

The multiple layers of thin DF veneer enhances the structural uniformity and increases the strength and reliability of our American made A PLANK.

Strength and Stiffness Verification

• Every A PLANK is individually proof tested to insure that each plank meets OSHA deflection limits before

being branded as a scaffold plank

• Modulus of Rupture and Modulus of Elasticity are frequently tested throughout the LVL production process in accordance with the requirements of APA-EWS an independent third party inspection agency.

• A PLANK is designed to conform to ANSI A10.8-2001 Loading Requirements.

Applicable Design Standards

• ICBO 1997 Uniform Building Code Structural Laminated Veneer Lumber

• U.S. Occupational Safety and Health Administration, OSHA Scaffold Standards (29 CFR 1910 & 1926)

• ANSI A10.8-2001, Safety Requirements for Scaffolding

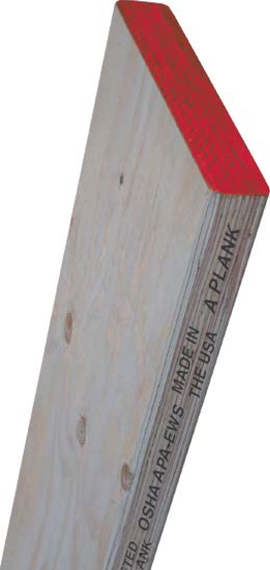

Plank Embossing

• Each plank is permanently embossed with the following:

A PLANK MADE IN USA OSHA APA-EWS

1081 "Production Date" PROOF TESTED SCAFFOLD PLANK

• Scarfed face joints for a smooth flat working surface

• Eased edges for splinter free handling

| Allowable Span Table |